Introduction

CNC steel machining represents the epitome of precision and efficiency in modern manufacturing. As industries continue to demand high-quality, intricate steel components with tight tolerances, CNC (Computer Numerical Control) machining has emerged as a critical technology in meeting these needs. This article delves into the complexities of CNC steel machining, exploring its processes, benefits, applications CNC steel parts challenges, and future developments.

What is CNC Steel Machining?

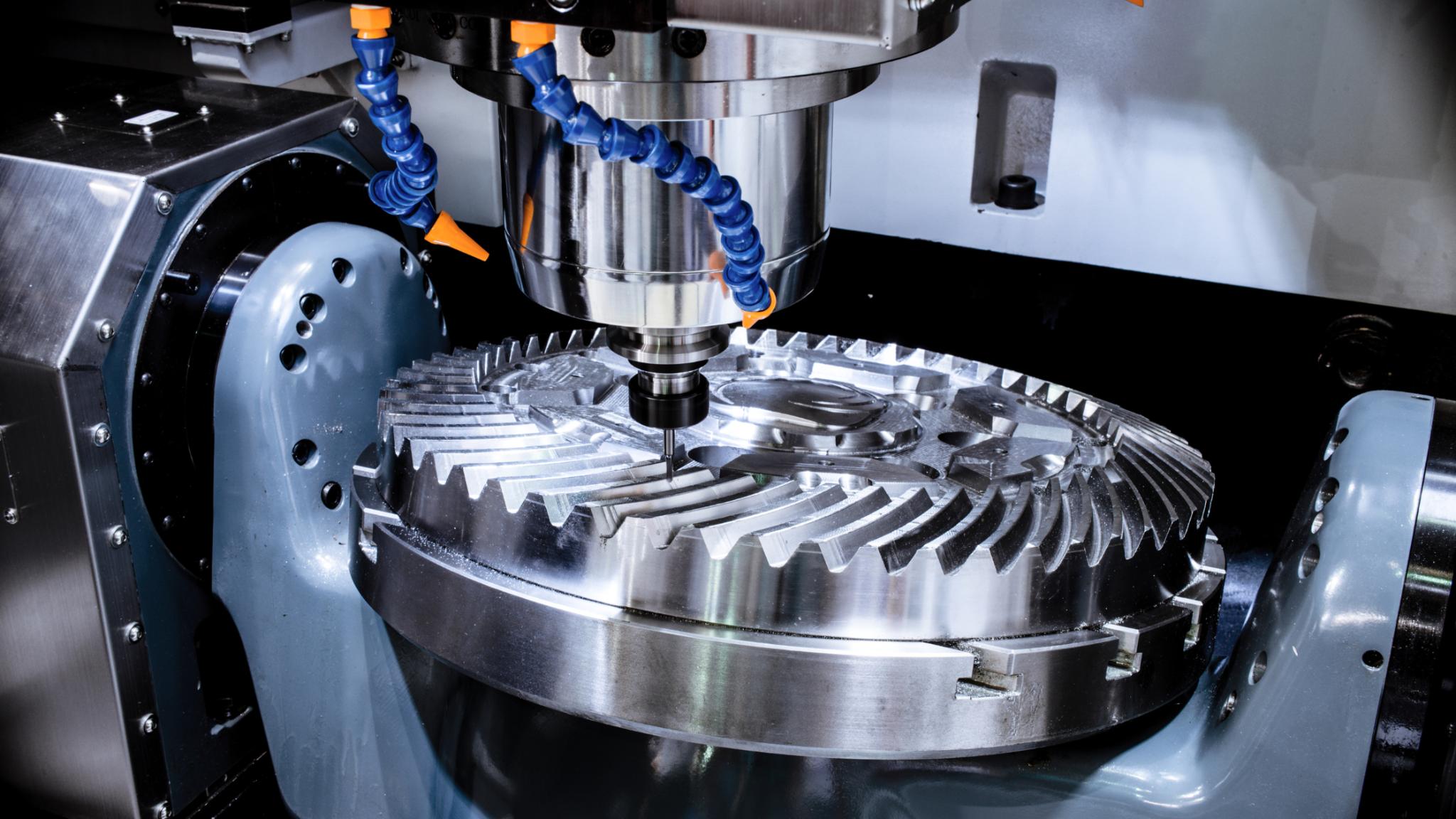

CNC steel machining involves using computer-controlled machines to precisely cut, shape, and finish steel components. The integration of computer technology with traditional machining methods has revolutionized the manufacturing industry, enabling the production of complex parts with unmatched accuracy and repeatability.

The Basics of CNC Machining

- Computer Control: CNC machines operate based on computer programs that dictate the movements and operations of the machine tools. These programs are created using CAD (Computer-Aided Design) software and converted into G-code, which the CNC machine interprets to execute specific machining tasks.

- Precision and Accuracy: One of the primary advantages of CNC machining is its ability to produce components with extremely tight tolerances. The precision of CNC machines is achieved through the exact control of cutting tools and movement along multiple axes.

- Automation: CNC machining automates the production process, reducing the need for manual intervention. This automation enhances efficiency and consistency, allowing for high-volume production with minimal variability.

CNC Machining Processes for Steel

Various CNC machining processes are employed to work with steel, each suited for different types of operations and applications. Understanding these processes is crucial for selecting the appropriate technique based on the desired outcomes.

1. CNC Milling

- Description: CNC milling uses rotary cutters to remove material from a steel workpiece. The cutting tool rotates while the workpiece is fed into the tool along different axes to achieve the desired shape and dimensions.

- Applications: CNC milling is ideal for producing complex shapes, slots, and surface finishes. It is commonly used in aerospace, automotive, and industrial applications where precision and intricate designs are required.

2. CNC Turning

- Description: CNC turning involves rotating a steel workpiece while a stationary cutting tool removes material to create cylindrical parts. The machine tool moves along various axes to achieve precise dimensions and surface finishes.

- Applications: CNC turning is employed for manufacturing cylindrical components such as shafts, pins, and bushings. It is widely used in automotive, machinery, and medical device industries for parts requiring high precision and durability.

3. CNC Drilling

- Description: CNC drilling utilizes rotating drill bits to create holes in a steel workpiece. The CNC machine controls the drill’s position and depth, ensuring accurate hole placement and dimensions.

- Applications: CNC drilling is essential for producing holes, slots, and openings in steel components. It is crucial for applications requiring precise hole sizes and locations, such as structural components and assembly parts.

4. CNC Grinding

- Description: CNC grinding uses abrasive wheels to achieve fine surface finishes and precise dimensions. The grinding process removes material from the steel workpiece to achieve the desired surface quality and tolerance.

- Applications: CNC grinding is used for finishing operations and achieving tight tolerances. It is commonly employed in producing high-precision components for aerospace, automotive, and tooling industries.

5. CNC Electrical Discharge Machining (EDM)

- Description: CNC EDM employs electrical discharges to erode material from the steel workpiece. This process involves creating a series of electrical sparks between an electrode and the workpiece to achieve intricate shapes and features.

- Applications: CNC EDM is valuable for producing complex shapes and detailed features on hard steel materials. It is often used in tool and die making, as well as for manufacturing intricate parts in aerospace and medical industries.

Future Trends in CNC Steel Machining

The field of CNC steel machining is continually evolving, with new advancements and trends shaping its future. Staying informed about these trends is essential for leveraging the latest technologies and maintaining a competitive edge.

1. Integration with Additive Manufacturing

- Description: The combination of CNC machining with additive manufacturing (3D printing) offers new possibilities for producing complex geometries and customized parts. This integration enhances design flexibility and manufacturing efficiency.

- Applications: Integrating CNC machining with additive manufacturing allows for the creation of intricate components with optimized designs and reduced material waste. This approach supports the production of high-performance parts with advanced features.

2. Advancements in Materials

- Description: The development of new steel alloys and composite materials with improved properties will expand the capabilities of CNC machining. These materials offer enhanced performance, strength, and durability for various applications.

- Applications: New materials will enable the production of high-performance components for industries such as aerospace, automotive, medical, and oil and gas. CNC machining will adapt to handle advanced materials with specialized properties.

3. Increased Automation and Robotics

- Description: The integration of automation and robotics in CNC machining will improve efficiency and reduce manual intervention. Automated systems for tool changes, workpiece handling, and inspection will streamline production processes.

- Applications: Automation and robotics will enhance productivity, consistency, and accuracy in CNC machining operations, supporting high-volume production and complex manufacturing tasks. Automated systems will contribute to reduced lead times and improved overall efficiency.

4. Artificial Intelligence and Machine Learning

- Description: The application of artificial intelligence (AI) and machine learning in CNC machining will enable predictive maintenance, process optimization, and real-time quality control. These technologies will enhance the performance and reliability of machining operations.

- Applications: AI and machine learning will improve decision-making, reduce downtime, and optimize machining processes, leading to higher efficiency and quality in steel CNC machining services. These technologies will contribute to smarter manufacturing and data-driven insights.

5. Sustainability and Green Manufacturing

- Description: The focus on sustainability and green manufacturing will drive advancements in CNC machining practices, including energy-efficient operations and reduced environmental impact. Manufacturers will adopt eco-friendly materials and processes to minimize their carbon footprint.

- Applications: Sustainable CNC machining practices will contribute to environmental conservation and promote responsible manufacturing practices. Implementing energy-efficient technologies and recycling materials will support greener manufacturing processes.

Conclusion

CNC steel machining represents a cornerstone of precision engineering, offering a blend of accuracy, efficiency, and versatility for producing high-quality steel components. The continued evolution of CNC technology, combined with advancements in materials, automation, and sustainability, will shape the future of steel machining. By understanding the intricacies of CNC machining and staying abreast of emerging trends, manufacturers can harness the full potential of this technology to drive innovation and excellence in steel component production. CNC steel machining not only meets the demands of modern manufacturing but also sets the standard for precision and performance across various industries.