In the world of manufacturing and construction, fastening two materials together is a crucial process. There are many ways to do this, such as welding, bolting, or using adhesives. One efficient and widely used method is riveting. Among different types of rivets, self-piercing rivets stand out as a strong and reliable option. But what exactly is a self-piercing rivet, and how does it work? Let’s explore this topic in detail.

What Is a Self-Piercing Rivet?

A self-piercing rivet (SPR) is a special type of rivet designed to join two or more materials without needing a pre-drilled hole. Unlike traditional rivets, which require holes before insertion, self-piercing rivets pierce through the top layer of material and form a strong joint without completely passing through the bottom layer. This process creates a tight and durable connection.

Self-piercing rivets are commonly used in industries like automotive, aerospace, and construction. They are especially useful for joining materials that are difficult to weld, such as aluminum and steel.

How Does a Self-Piercing Rivet Work?

The process of installing a self-piercing rivet is simple yet highly effective. Here’s how it works:

- Placing the Materials — The materials that need to be joined are stacked on top of each other in the correct position.

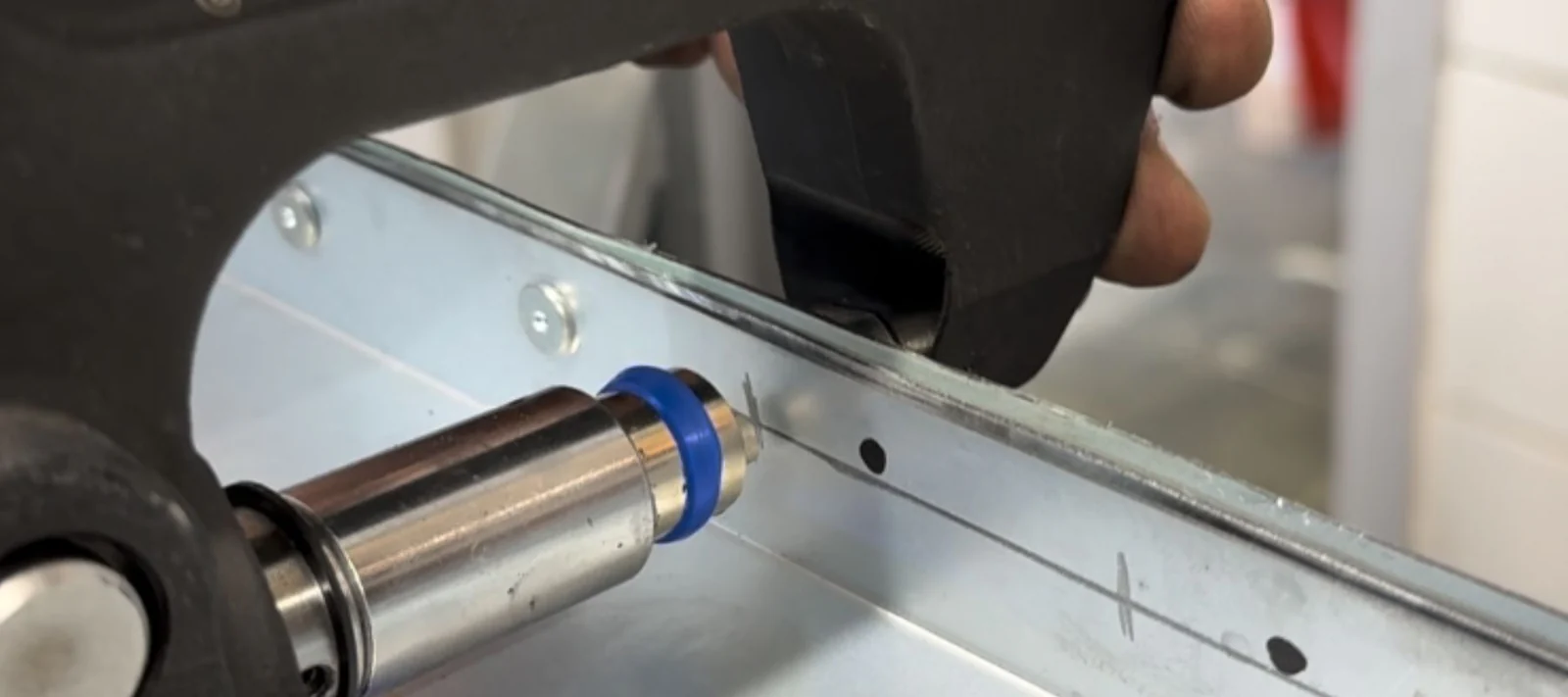

- Inserting the Rivet — A self-piercing rivet is positioned on the top material using a rivet gun or machine.

- Applying Force — The rivet gun applies high pressure, forcing the rivet to pierce the top material.

- Forming the Joint — Instead of passing completely through the bottom layer, the rivet expands and forms a button-like shape on the underside, locking the materials together.

- Finalizing the Connection — The process results in a strong, airtight joint that does not require extra finishing steps.

This method is fast and efficient, making it ideal for industries that require high-speed production.

Advantages of Self-Piercing Rivets

Self-piercing rivets offer several benefits over traditional fastening methods. Here are some key advantages:

- No Pre-Drilled Holes Required

Traditional rivets need holes before they can be installed, but self-piercing rivets eliminate this step, saving time and effort.

- Strong and Durable Joints

The formed joint is strong, reliable, and resistant to vibrations, making it perfect for applications like automotive manufacturing.

- Works on Different Materials

Self-piercing rivets can join materials of different thicknesses and types, such as aluminum, steel, and composite materials.

- No Heat or Sparks

Unlike welding, which requires high temperatures, self-piercing riveting is a cold process. This reduces the risk of heat damage and makes it safer.

- Quick and Efficient

The installation process is fast, which increases productivity in industries where speed is important.

Where Are Self-Piercing Rivets Used?

Self piercing rivets are widely used in different industries because of their efficiency and strength. Here are some common applications:

- Automotive Industry

Many modern vehicles use lightweight materials like aluminum. Since welding aluminum can be difficult, self-piercing rivets are often used to assemble car bodies and frames.

- Aerospace Industry

Aircraft manufacturers use self-piercing rivets to join lightweight materials while maintaining structural integrity.

- Construction and Building

Self-piercing rivets help in constructing metal buildings, assembling window frames, and installing roofing materials.

- Electronics and Appliances

Small electronic devices and household appliances also use self-piercing rivets for strong and precise connections.

How to Choose the Right Self-Piercing Rivet

Selecting the right self piercing rivet depends on several factors, including:

- Material Type — Choose a rivet that is compatible with the materials being joined.

- Material Thickness — Different rivets work for different thicknesses; selecting the right size ensures a secure joint.

- Strength Requirements — Some applications require stronger rivets to withstand heavy loads or vibrations.

- Corrosion Resistance — In environments exposed to moisture or chemicals, corrosion-resistant rivets are necessary.

Conclusion

Self-piercing rivets are an innovative and efficient way to join materials without the need for pre-drilled holes or welding. They create strong, durable, and reliable joints, making them ideal for industries like automotive, aerospace, and construction. Their ability to work with different materials and their fast installation process make them a popular choice for modern manufacturing.

If you need a fastening method that is strong, quick, and easy to use, self-piercing rivets could be the perfect solution!