FAQs

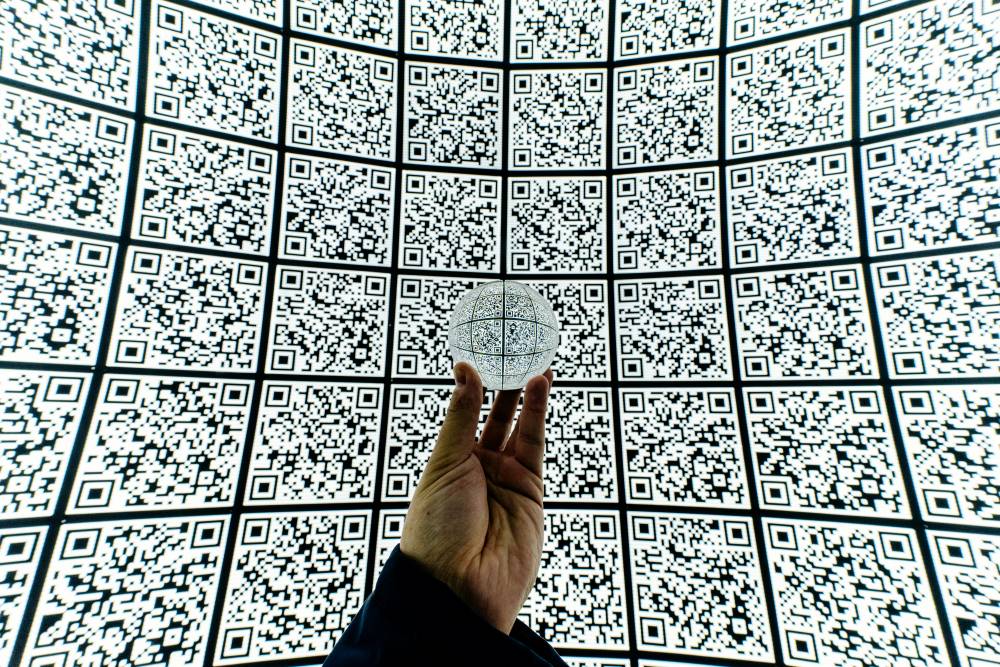

Inventory management has never been more important—or more complex—than it is today. With customer expectations rising, supply chains becoming more connected, and businesses under pressure to stay lean, organizations need smarter ways to track and manage their inventory. One technology has quickly moved from “nice to have” to an essential operational tool: QR codes.

In this article, you’ll learn how QR code labeling is reshaping workflows, improving accuracy, and giving businesses the real-time visibility they need to stay competitive.

The Shift From Manual Tracking to Smart, Automated Systems

Traditional inventory methods—clipboards, spreadsheets, and outdated manual entry—often create bottlenecks and errors. As businesses grow, these issues multiply, leading to miscounts, stockouts, and lost revenue.

QR codes offer a modern alternative. Unlike barcodes, which store limited information, QR codes can hold significantly more data and can be scanned from any angle. This makes it easier for employees to capture accurate information instantly.

Businesses are adopting QR-based systems because they are:

-

Affordable to create and print

-

Fast to scan with phones or scanners

-

Flexible enough to store various types of data

-

More secure and tamper-resistant

With these advantages, teams can replace fragmented spreadsheets with fully integrated, real-time inventory tracking systems.

How QR Codes Improve Accuracy and Efficiency

Accuracy is essential in inventory management. A single mistake can trigger major supply chain issues. QR codes help prevent these problems with several efficiency-boosting benefits.

1. Real-Time Inventory Updates

When employees scan items as they arrive, move, or ship out, the system updates instantly. This removes the need for manual entry and drastically reduces the risk of discrepancies.

2. Faster Item Identification and Tracking

A quick scan reveals details such as:

-

Product name

-

Serial or batch numbers

-

Supplier information

-

Expiration dates

-

Storage instructions

-

Current stock levels

This helps workers access accurate data without needing to cross-check on paper or spreadsheets.

3. Better Supply Chain Transparency

Teams across purchasing, receiving, warehousing, and shipping gain a unified view of inventory levels. This improves forecasting and reduces communication gaps.

Streamlined Processes Across Every Stage of Inventory Management

QR code labeling goes beyond simple counting—it enhances every step of the inventory process.

Receiving

Upon arrival, items can be scanned to confirm shipment accuracy, record quantities, assign storage locations, and trigger automated audits.

Storage and Organization

QR labels on bins, shelves, pallets, and products make put-away and retrieval faster. Workers know exactly where items belong.

Picking and Packing

Pickers can scan items as they select them, ensuring accuracy before packaging. This reduces the likelihood of shipping incorrect orders.

Shipping

Scanning packages at each checkpoint improves traceability. Customers can even access tracking updates through QR codes on their shipments.

Why Modern Businesses Prefer QR Codes Over Traditional Barcodes

While barcodes remain useful, they can’t meet the demands of modern, fast-paced inventory environments. QR codes offer several advantages:

-

They store far more data than barcodes.

-

They scan reliably even when scratched or partially damaged.

-

They integrate with apps, cloud platforms, and digital workflows.

-

They can be scanned by nearly any smartphone.

These benefits explain why QR Code Labels have become a leading choice for businesses focused on efficiency and accuracy.

QR Code Use Cases Across Multiple Industries

QR code inventory systems offer value in a wide range of sectors.

Retail

Stores use QR codes for easier stock checks, faster replenishment, and more efficient cycle counts.

Manufacturing

Production teams track raw materials, monitor component flow, and maintain quality control throughout the line.

Healthcare

Hospitals apply QR codes to equipment and supplies, helping reduce shortages and maintain accurate usage records.

Logistics

Delivery networks use QR codes for real-time shipment visibility, reducing lost or misplaced items.

Small Businesses

Even small online sellers use QR systems to organize inventory and manage packaging more efficiently.

Better Data Leads to Smarter Decisions

One of the biggest advantages of QR-based systems is effortless data collection. Over time, this data reveals patterns such as:

-

High-demand products

-

Seasonal trends

-

Supplier consistency

-

Areas of shrinkage or waste

-

Ideal reorder points

These insights help businesses optimize stock levels, reduce costs, and improve overall supply chain performance.

How to Get Started With QR Code Inventory Labels

Implementing a QR system is simpler than many expect. Here’s how to begin:

-

Choose an inventory system that supports QR codes.

-

Generate QR codes for products, shelves, or storage locations.

-

Print durable labels suited for your environment.

-

Train staff on scanning and updating data.

-

Roll out the system gradually, starting with a small section or product category.

Most businesses notice improvements within days.

Conclusion: QR Codes Are Powering the Future of Inventory Management

As businesses aim to improve accuracy, reduce costs, and streamline operations, QR code labeling stands out as one of the most practical solutions available. From receiving to shipping, QR codes enhance visibility, speed, and decision-making at every stage of the inventory process.

For organizations looking to work smarter—not harder—adopting QR-based inventory systems is a powerful step toward modernizing operations and building a more efficient future.

1. Are QR codes better than barcodes for inventory management?

Yes. QR codes store more information, scan more reliably, and integrate better with modern digital systems.

2. Do I need special equipment to scan QR codes?

No. Most smartphones and tablets can scan QR codes with built-in or app-based scanners.

3. Can QR codes work in harsh environments?

Yes. When printed on durable materials, they can withstand heat, moisture, chemicals, and rough handling.

4. Are QR codes difficult to implement?

Not at all. Most businesses can roll out a basic QR-based system in a few days with minimal training.

5. Do QR codes improve order accuracy?

Yes. Scanning items during picking and packing ensures orders are consistent, accurate, and recorded in real time.