What are the common signs that a hydraulic cylinder needs fixing?

Hydraulic cylinders play a critical role in powering various machines, from heavy construction equipment to manufacturing systems. When something goes wrong with a hydraulic cylinder, it can cause significant downtime and frustration. Consulting a hydraulic cylinder repair company can help address these issues promptly and prevent more severe damage. Knowing the warning signs early can save you money and minimize downtime. In this article, we'll explore the most common signs that a hydraulic cylinder needs fixing, giving you the insight to act before the situation worsens.

Understanding the Basics of Hydraulic Cylinders

Before diving into the signs of trouble, it’s important to understand what a hydraulic cylinder does. Essentially, it’s a mechanical actuator that generates force using hydraulic fluid. These cylinders are essential for lifting, pushing, or pulling heavy loads in equipment such as excavators, forklifts, and presses. The system's efficiency depends on maintaining consistent pressure and smooth motion. When something goes wrong, the whole operation can grind to a halt.

Why Maintenance Matters for Hydraulic Cylinders

Regular maintenance is key to keeping hydraulic cylinders in top shape. Over time, wear and tear can cause internal and external problems. Neglecting these issues may lead to costly repairs or even total equipment failure. Keeping an eye on performance and addressing small issues promptly ensures longevity and reliability.

Signs Your Hydraulic Cylinder Needs Fixing

Let’s dive into the specific indicators that suggest your hydraulic cylinder might be in trouble.

Unusual Noises During Operation

One of the first signs something isn’t right is hearing strange noises. If you notice banging, clanking, or hissing sounds while the cylinder is operating, it could indicate internal damage or leaks. These noises often suggest that air has entered the hydraulic system, disrupting smooth operation.

Fluid Leaks Around the Cylinder

Leaks are perhaps the most obvious sign of a problem. If you see hydraulic fluid pooling around the cylinder or notice that the equipment isn’t maintaining proper pressure, there’s likely a seal failure. Worn or damaged seals allow fluid to escape, reducing the system’s efficiency and creating safety hazards.

Slow or Uneven Movement

When a hydraulic cylinder starts moving sluggishly or erratically, it’s a clear red flag. This could be due to worn-out components, contamination in the hydraulic fluid, or internal pressure imbalances. Addressing this issue early can prevent further damage to the system.

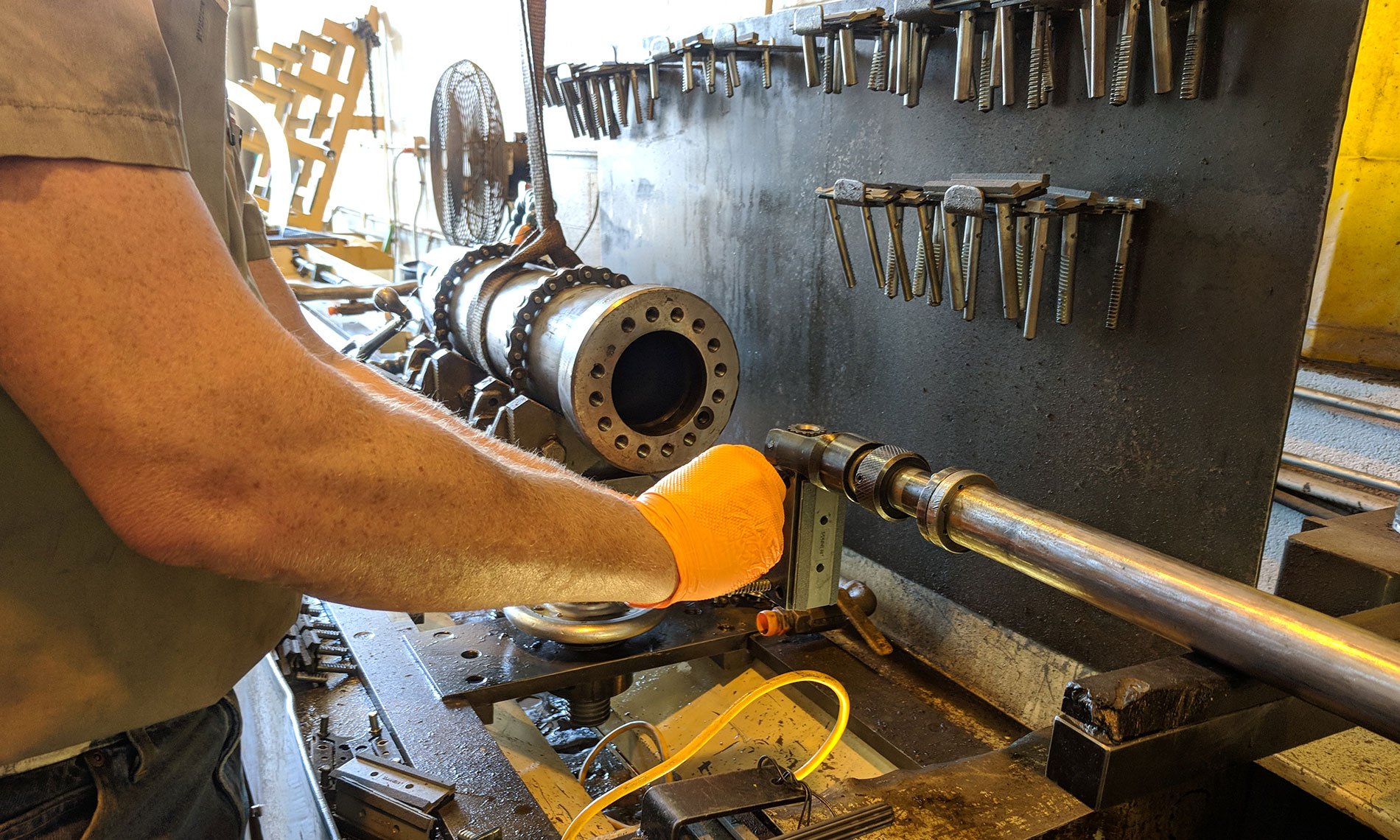

Visible Damage to the Cylinder

Take a close look at the cylinder itself. If you notice dents, cracks, or corrosion, these physical signs of damage can compromise the cylinder's performance. Even minor wear on the piston rod can escalate into significant mechanical problems if left unaddressed.

Overheating of the System

Hydraulic systems generate heat, but excessive heat indicates a problem. Overheating often results from clogged filters, low fluid levels, or internal friction within the cylinder. If you frequently experience overheating, it’s time to inspect the cylinder and surrounding components.

Loss of Power or Pressure

A drop in performance is another key sign. If the hydraulic cylinder can no longer lift, push, or pull with its usual force, it may indicate internal leaks or worn-out seals. Pressure loss affects not just the cylinder but the entire system’s functionality.

Jerky or Inconsistent Operation

Smooth motion is essential for hydraulic cylinders to work effectively. When a cylinder begins operating jerkily or inconsistently, it’s often a symptom of air in the system, damaged seals, or uneven fluid distribution. Ignoring this issue can strain other components, leading to larger failures.

Diagnosing Hydraulic Cylinder Problems

Once you notice one or more of these signs, the next step is to diagnose the issue accurately. Professionals often use tools like pressure gauges, fluid analyzers, and visual inspections to pinpoint the problem. Identifying the root cause early can save time and money in repairs.

Fixing Common Hydraulic Cylinder Issues

Depending on the problem, repairs may involve replacing seals, rods, or pistons. Sometimes, a complete cylinder rebuild is necessary. Always consult with a qualified technician for complex issues to ensure safety and proper repairs.

Can You Prevent These Issues?

Absolutely! Prevention is better than cure. Regularly checking for leaks, maintaining proper fluid levels, and cleaning the system can go a long way in keeping your hydraulic cylinder in good condition. Investing in preventive maintenance reduces the risk of sudden failures and extends the equipment’s lifespan.

When Should You Call a Professional?

While some minor issues can be handled in-house, like tightening fittings or topping up hydraulic fluid, larger problems require expert attention. If you’re dealing with major leaks, significant pressure loss, or visible damage, it’s best to call a professional to avoid further complications.

Final Thoughts

Hydraulic cylinders are the workhorses of many machines, and any malfunction can disrupt operations. By keeping an eye out for the common signs we’ve discussed—such as leaks, unusual noises, and performance loss—you can catch issues early and avoid costly repairs. Regular maintenance and timely interventions will ensure your equipment runs smoothly and efficiently. Remember, if you’re ever in doubt, consulting a professional is the safest course of action.

Related Courses and Certification

Also Online IT Certification Courses & Online Technical Certificate Programs